The Acceptable Quality Level (AQL) is a standard used to measure the quality of products. According to ISO 2859-1, it is defined as the "worst tolerable" quality level. During random sampling quality inspections, the AQL indicates the number of defective components that are considered acceptable. This is typically expressed as a percentage or ratio of the total quantity of inspected products.

Quality Assurance inspectors use the ISO 2859 standard and its tables when inspecting products. This international standard has equivalents in national regulations like ANSI/ASQC Z1.4, NF06-022, BS 6001, and DIN 40080.

A method commonly used in sampling inspection is AQL (Acceptable Quality Limit) Sampling. This method helps determine if a production order meets the client's specifications by testing a sample of the products. The customer can decide whether to accept or reject the entire order based on the results.

The inspection report you receive will indicate whether your production has passed or failed the selected Acceptable Quality Tolerance level.

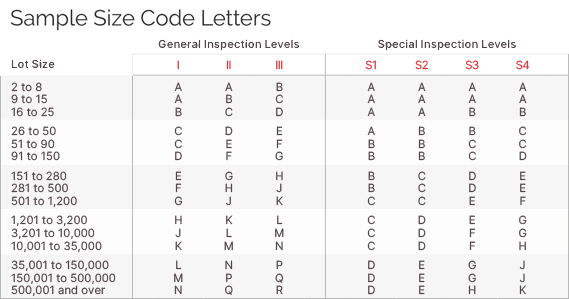

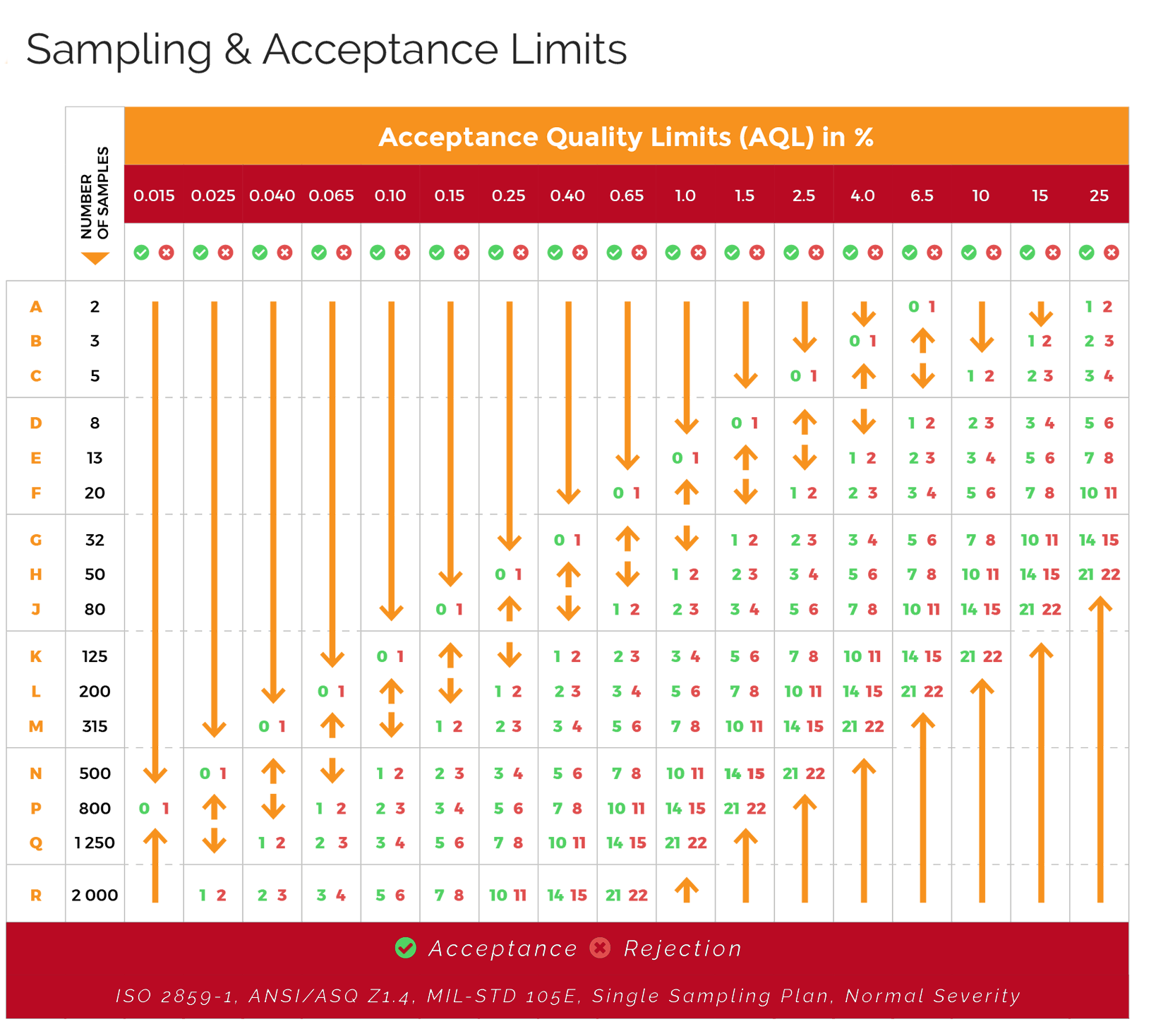

The AQL tables that the calculator is based on Following Tow Tablets:

You can use our sampling calculation tool to test your product inspection AQL to determine the correct sample size and acceptance number.

For example, let's say you need to inspect 4000 pieces of Tablets, and your organization has selected a normal inspection - level II and an AQL of 2.5.

You can input these details, including the quantity, inspection level, and AQL values, into the tool to determine the appropriate sample size and acceptance number.

Critical defects: Critical defects are defects that can cause severe harm to the end-user. Importers usually set an AQL of 0.0 for critical defects, meaning that if even one critical defect is found in the sample size, the entire order will fail the inspection.

Major defects: Major defects are defects that are less serious but still increase the risk of product failure and are not acceptable to end-users. Importers typically set an AQL standard of 2.5% for major defects.

Minor defects: Minor defects are small defects that have a low impact on safety and the usability of the product. Most importers set an AQL standard of 4% for minor defects.