Standard Operating Procedure for Laundry Management in Pharmaceuticals

SOP for Laundry Management in Pharmaceuticals

1. Purpose:

To provide a standard operating procedure for Laundry Management (Washing and upkeeping of garments) in Pharmaceuticals.

2. Scope

The scope of this SOP is applicable for Laundry Management (Washing and upkeeping of garments) in Pharmaceuticals. at [company name].

3. Responsibility

Linen management person: Storage of garments in linen storage and issuance room, issuance of garments to change rooms, collection of garments and sending them for washing, receipt of washed and ironed garments from laundry, and maintenance of garment movement record.

HR and Administration: To ensure compliance with the procedure

Laundry service provider: To receive garments to be washed and return washed and ironed garments to the linen management person.

4. Definitions

Not applicable

5. Procedure

5.1 Storage of garments in linen room:

• Store the washed and ironed garments in the garment cabinets according to the department, sections, and color-coding.

• Arrange the garments in such a way that size of the garments are visible, and that will enable quick issuance of garments as per requirement.

• Keep the garment cabinet in closed condition after issuance.

• Cabinet in which garments are stored are maintained with adequate naming and numbering to make the issuance process easy and quick.

5.2 Submission of garments to laundry service:

• To collect the garment from the used garment collection bin by a linen management person.

• Segregate the garments according to color code and store them in separate bags and record the number of garments in the record for garment submission to a laundry.

• To collect the garments and acknowledge the receipt of garments by laundry service person will.

Send the collected garments for washing and ironing purposes.

5.3 Receipt of garments from laundry service:

• Once washed and garments are received, the linen management person needs to count the received garments according to the record and store them in the respective cabinet.

• In case garment count is less, a linen management person should ensure the reason for that. If any discrepancy is noted, the linen management person needs to inform HR and the Admin person to handle the discrepancy.

• Record the details of received garments in the garment inward register and store it in the linen room.

5.4 Entry and exit procedure for entering and exiting from linen issuance room:

• Wear shoe cover, hair net, overcoat, nose mask, and hand gloves while entering the linen issuance room at a marked palace near the room’s entry door.

• While working in the linen room, linen management personnel need to maintain the gowning to prevent contamination of gown.

• While exiting the room, place the overcoat in the used garment bin, discard the shoe cover, hair net, mask, and hand gloves in the waste bin.

5.5 Issuance of garments to the change rooms

• Daily, before the start of the shift, the linen management person shall place the garments in the change room racks.

• For different departments, separate racks are provided to place the garments.

• Stake the garments in the rack so that sizes of the garments are visible so that it can be easy to pick.

5.6 Procedure for receipt of laundry at laundry service provider’s premises:

• On receipt of garments for washing, ensure that garments are received in a segregated manner as per color coding.

• In case any garment is mixed, it will be segregated and mixed with respect to color code.

• Garment shall be placed on the racks labeled “Garments to be washed”.

5.7 Procedure for washing and drying of garments:

• Personnel handling the washing and drying area garment shall wear a clean overcoat, shoe cover, hair net, hand gloves, and nose mask.

• Different color-coded garments shall be washed separately.

• Number or amount of garment to be placed in the washing machine as per validated load.

• Once the washing is completed, a drying cycle shall be run to dry the garments. Ensure that clothes are not in wet condition.

• Once the garments are dried, they shall be unloaded and placed at a clean garment area labeled as “washed garments for ironing”.

5.8 Procedure for garment inspection, ironing, folding, and packing:

• Personnel handling the garment shall wear a clean overcoat, shoe cover, hair net, hand gloves, and nose mask.

• Washed and dried garments shall be inspected to ensure that they are not torn, adequately cleaned, and do not have any stain or extraneous material.

• If any abnormality is observed, it shall be segregated for required correction.

• After inspection, garments shall be ironed and folded as per folding instructions displayed for each type of garment.

• Folded garments shall be packed and stored in the packets and stacked in the clean garment cabinet labeled “clean garment ready to dispatch”. Garments shall be stored separately according to the color-coding.

• Garments shall be sent to the linen room according to daily demand.

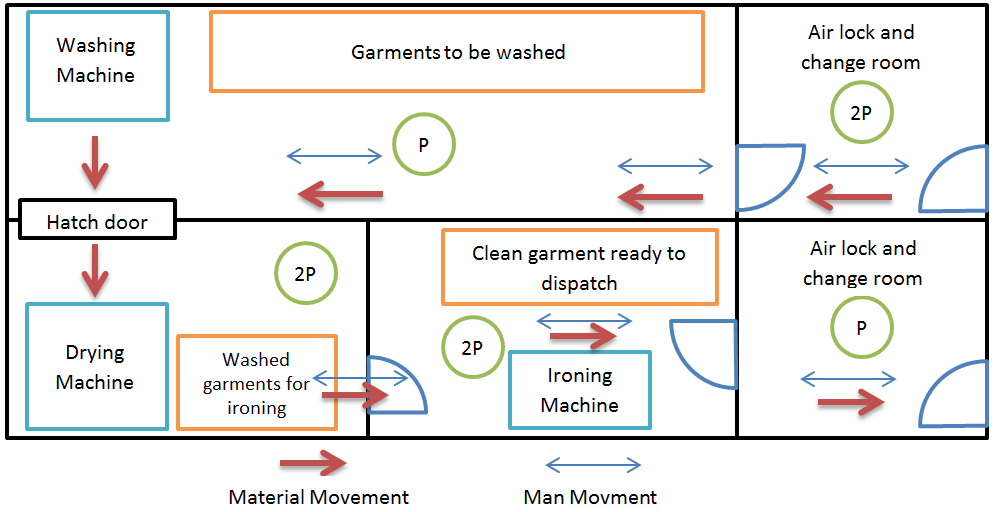

5.9 Laundry facility maintenance and man and material flow in the laundry:

• Laundry shall be maintained with area classification of ISO Class 8 at rest condition.

• Personnel working in the laundry shall wear a clean overcoat, shoe cover, hair net, hand gloves, and nose mask.

• The following shall be a man and material movement in the laundry facility.

6. Frequency

Wearing fresh garments: Daily

Washing and drying of cloths: As and when cloths received for washing

7. Formats

7.1 Format for Garment management

| Sr. No. | Date | Types of garments sent for washing | Count | Submitted by | Received by | Garments discarded (if any) with reason | Washed garments returned by | Received by | Remark |