750+ Pharmaceutical Interview Questions and Answers for the year 2022-23

Technical know-how is a must to clear the pharmaceutical interview. Most of the answers are based on basic knowledge and current pharmaceutical guidelines. Here, we have compiled interview questions and answers, most common during the interview for pharmaceutical jobs for working in an oral solid manufacturing facility, sterile manufacturing facility, quality assurance, microbiology, or validation department.

The questions and answers will help pharma freshers, beginners, and experienced individuals. Freshers and beginners can understand what types of questions could be asked and the answers to those questions. Experienced pharma professionals can refresh their basic knowledge, and the questions and answers will help them while interviewing other pharma professionals during the recruitment process.

- Top 15 interview tips for Pharma Professionals

- Pharmaceutical Interview Questions and Answers on General Topic

- Pharmaceutical Interview Questions and Answers on Production System – Oral Solid Dosage Formulation

- Pharmaceutical Interview Questions and Answers on Production System – Sterile and Injectable Dosage Formulation

- Pharmaceutical Interview Questions and Answers on Validation

- Pharmaceutical Interview Questions and Answers on Microbiology

- Useful Interview Questions and Answers on HPLC and Troubleshooting

- Pharmaceutical interview Questions and Answers for quality control Laboratory

Mostly asked 10+ General Pharmaceutical Interview Questions and Answers for 2021-2022

Most commonly asked general questions and answers for the freshers in the pharmaceutical industry. Even though freshers have good knowledge about subjects, following are few general questions which interviewer will expect that candidate must have to know about as it is very basic knowledge and connecting bridge between student life and industry life.

1. What is the Good Manufacturing Practice (GMP) or Current Good Manufacturing Practice (CGMP)? Provide reference to GMP regulations of different countries.

Quality of pharmaceuticals is important for the patient’s safety and are very carefully regulated by respective country regulators.

GMP or CGMP refers to the Current Good Manufacturing Practice regulations enforced by the respective country regulations.

GMP provides systems that assure proper design, monitoring, and control of manufacturing processes and facilities. Adherence to the GMP regulations assures the identity, strength, quality, and purity of drug products by requiring that manufacturers of medications adequately control manufacturing operations.

The US FDA uses terminology CGMP. According to the U.S. FDA, “‘C’ in CGMP stands for “current,” requiring companies to use technologies and systems that are up-to-date in order to comply with the regulations. Systems and equipment that may have been “top-of-the-line” to prevent contamination, mix-ups, and errors 10 or 20 years ago may be less than adequate by today’s standards.”

GMP regulations governed by different countries and its reference guidance are detailed as follows. Following table provides reference for most common regulatory bodies. This will provide understanding on how GMP regulations are forced by different regulatory bodies.

| Country | Regulatory Body | Reference regulations under respective country’s law |

| United States | U.S. FDA | Code of Federal Regulations (CFR): 21 CFR Part 210. Current Good Manufacturing Practice in Manufacturing Processing, packing, or Holding of Drugs. 21 CFR Part 211. Current Good Manufacturing Practice for Finished Pharmaceuticals. 21 CFR Part 212. Current Good Manufacturing Practice for Positron Emission Tomography Drugs. 21 CFR Part 600. Biological Products: General. 21 CFR Part 314. For FDA approval to market a new drug. |

| European Union (EU) Countries | European Commission – Health and Food Safety | The entire body of EU medicines legislation (EudraLex) is compiled in “The rules governing medicinal products in the European Union”. Pharmaceutical sector is compiled in Volume 1 and Volume 5 of the publication “The rules governing medicinal products in the European Union”: Volume 1 – EU pharmaceutical legislation for medicinal products for human use Volume 5 – EU pharmaceutical legislation for medicinal products for veterinary use |

| Countries following WHO guidance | World Health Organization (WHO) | WHO good manufacturing practices for pharmaceutical products: main principles, Annex 2, WHO Technical Report Series 986, 2014 |

| India | Ministry of health and family welfare | The drugs and cosmetics act, 1940 and The drugs and cosmetics rules, 1945 Schedule M: Good Manufacturing Practices and requirements of premises, plant and equipment for pharmaceutical products |

| Canada | Health Canada | Good Manufacturing Practices Guidelines by Health Products and Food Branch Inspectorate Good Manufacturing Practices (GMP) refer to Division 2, Part C of the Food and Drug Regulations. The guidelines apply to pharmaceutical, radiopharmaceutical, biological, and veterinary drugs and were developed by Health Canada in consultation with their stakeholders. Division 1A, Part C of the Food and Drug Regulations defines activities for which GMP compliance is to be demonstrated prior to the issuance of an establishment license. Guidance based on PIC/S |

| Japan | Pharmaceuticals and Medical Devices Agency (PMDA) | Pharmaceuticals and Medical Devices Agency (PMDA) was established and came into service on April 1, 2004, under the Law for the Pharmaceuticals and Medical Devices Agency, as a consolidation of the services of the Pharmaceuticals and Medical Devices Evaluation Center of the National Institute of Health Sciences (PMDEC), the Organization for Pharmaceutical Safety and Research (OPSR/KIKO), and part of the Japan Association for the Advancement of Medical Equipment (JAAME). GMP Ministerial Ordinance (Ministerial Ordinance on Standards for Manufacturing Control and Quality Control for Drugs and Quasi-drugs) No. 179, 2004 |

| Australia | Therapeutic Goods Administration | AUSTRALIAN CODE OF GOOD MANUFACTURING PRACTICE FOR MEDICINAL PRODUCTS Therapeutic Goods Act 1989. This upholds the main objective of the Act, which is to ensure the safety, quality, efficacy and timely supply of therapeutic goods for Australian consumers. Guidance based on PIC/S |

| New Zealand | Medsafe | New Zealand Code of Good Manufacturing Practice for Manufacture and Distribution of Therapeutic Goods Part 1: Manufacture of Pharmaceutical Products (2009) Guidance based on PIC/S |

2. What is Standard Operating Procedure (SOP)?

SOPs are documented Standards Operating Procedure, authorized by the Quality Unit or Quality Assurance department having sets of written instructions to be followed by employees on a day to day basis to carry out operations in a consistent manner to achieve predetermined specification and a quality end-result.

Examples of Standard Operating Procedures are as follows:

– SOP for entry and exit in the manufacturing facility

– SOP for operation and cleaning of compression machine

– SOP for preparation of SOP

– SOP for pest control

– SOP for material receipt

– SOP for preventive maintenance program

– SOP for operation of High Performance Liquid Chromatography (HPLC) instrument

3. What is the typical content of Standard Operating Procedure (SOP)?

Objective or Purpose

Scope

Responsibility

Accountability

Definitions

Abbreviations

Reference

Procedure

List of Annexes

Format for recording Revision history

4. What is Master Formula Record, Master Formula, Manufacturing Formula, and Master Production and Control Record?

Master Formula Record, Master Formula, Manufacturing Formula, and Master Production and Control Record mean the same thing. This is an approved master document that describes the full manufacturing process of the drug product. [Reference: 1]

5. What is drug substance?

Drug substance is an active ingredient that is intended to furnish pharmacological activity or other direct effect in the diagnosis, cure, mitigation, treatment, or prevention of disease or to affect the structure or any function of the human body, but does not include intermediates used in the synthesis of such ingredient. [Reference: 2]

6. What is drug product?

Drug product means a finished dosage form, for example, tablet, capsule, solution, etc., that contains an active drug ingredient generally, but not necessarily, in association with inactive ingredients. The term also includes a finished dosage form that does not contain an active ingredient but is intended to be used as a placebo. [Reference:3]

7. What is Active ingredient?

Active ingredient means any component that is intended to furnish pharmacological activity or other direct effect in the diagnosis, cure, mitigation, treatment, or prevention of disease, or to affect the structure or any function of the body of man or other animals. The term includes those components that may undergo chemical change in the manufacture of the drug product and be present in the drug product in a modified form intended to furnish the specified activity or effect. [Reference:3]

8. Fiber means?

Fiber means any particulate contaminant with a length at least three times greater than its width. [Reference:3]

9. What is inactive ingredient?

Inactive ingredient means any component other than an active ingredient. [Reference:3]

10. What is Gang-printing?

Gang-printed labeling means labeling derived from a sheet of material on which more than one item of labeling is printed. [Reference:3]

11. What is full form of ICH?

Full form of ICH is International Council for Harmonisation (ICH), formerly known as the International Conference on Harmonisation (ICH).

12. ICH Guidelines are divided into how many categories? What are those?

The ICH topics are divided into the four categories below.

Quality Guidelines

Safety Guidelines

Efficacy Guidelines

Multidisciplinary Guidelines

13. How many main topic quality guidelines are published by ICH ?

Q1A – Q1F Stability

Q1A(R2) Stability Testing of New Drug Substances and Products

Q1B Stability Testing : Photostability Testing of New Drug Substances and Products

Q1C Stability Testing for New Dosage Forms

Q1D Bracketing and Matrixing Designs for Stability Testing of New Drug Substances and Products

Q1E Evaluation of Stability Data

Q1F Stability Data Package for Registration Applications in Climatic Zones III and IV

Q2 Analytical Validation

Q2(R1) Validation of Analytical Procedures: Text and Methodology

Q2(R2)/Q14 EWG Analytical Procedure Development and Revision of Q2 (R1) Analytical Validation

Q3A – Q3E Impurities

Q3A(R2) Impurities in New Drug Substances

Q3B(R2) Impurities in New Drug Products

Q3C(R8) Guideline for Residual Solvents

Q3C(R9) Maintenance EWG Maintenance of the Guideline for Residual Solvents

Q3D(R1) Guideline for Elemental Impurities

Q3D(R2) Maintenance EWG Revision of Q3D(R1) for cutaneous and transdermal products

Q3D training Implementation of Guideline for Elemental Impurities

Q3E EWG Impurity: Assessment and Control of Extractables and Leachables for Pharmaceuticals and Biologics

Q4A – Q4B Pharmacopoeias

Q4A Pharmacopoeial Harmonisation

Q4B Evaluation and Recommendation of Pharmacopoeial Texts for Use in the ICH Regions

Q4B Annex 1(R1) Residue on Ignition/Sulphated Ash General Chapter

Q4B Annex 2(R1) Test for Extractable Volume of Parenteral Preparations General Chapter

Q4B Annex 3(R1) Test for Particulate Contamination: Sub-Visible Particles General Chapter

Q4B Annex 4A(R1) Microbiological Examination of Non-Sterile Products: Microbial Enumeration Tests General Chapter

Q4B Annex 4B(R1) Microbiological Examination of Non-Sterile Products: Tests for Specified Micro-Organisms General Chapter

4C(R1) Microbiological Examination of Non-Sterile Products: Acceptance Criteria for Pharmaceutical Preparations and Substances for Pharmaceutical Use General Chapter

Q4B Annex 5(R1) Disintegration Test General Chapter

Q4B Annex 6 Uniformity of Dosage Units General Chapter

Q4B Annex 7(R2) Dissolution Test General Chapter

Q4B Annex 8(R1) Sterility Test General Chapter

Q4B Annex 9(R1) Tablet Friability General Chapter

Q4B Annex 10(R1) Polyacrylamide Gel Electrophoresis General Chapter

Q4B Annex 11 Capillary Electrophoresis General Chapter

Q4B Annex 12 Analytical Sieving General Chapter

Q4B Annex 13 Bulk Density and Tapped Density of Powders General Chapter

Q4B Annex 14 Bacterial Endotoxins Test General Chapter

Q4B FAQs Frequently Asked Question

Q5A – Q5E Quality of Biotechnological Products

Q5A(R1) Viral Safety Evaluation of Biotechnology Products Derived from Cell Lines of Human or Animal Origin

Q5A(R2) EWG Viral Safety Evaluation of Biotechnology Products Derived from Cell Lines of Human or Animal Origin

Q5B Analysis of the Expression Construct in Cells Used for Production of r-DNA Derived Protein Products

Q5C Quality of Biotechnological Products: Stability Testing of Biotechnological/Biological Products

Q5D Derivation and Characterisation of Cell Substrates Used for Production of Biotechnological/Biological Products

Q5E Comparability of Biotechnological/Biological Products Subject to Changes in their Manufacturing Process

Q6A- Q6B Specifications

Q6A Specifications : Test Procedures and Acceptance Criteria for New Drug Substances and New Drug Products: Chemical Substances

Q6B Specifications : Test Procedures and Acceptance Criteria for Biotechnological/Biological Products

Q7 Good Manufacturing Practice

Q7 Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients

Q7 Q&As Questions and Answers: Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients

Q8 Pharmaceutical Development

Q8(R2) Pharmaceutical Development

Q8/9/10 Q&As (R4) Q8/Q9/Q10 – Implementation

Q9 Quality Risk Management

Q9 Quality Risk Management

Q9(R1) EWG Quality Risk Management

Q8/9/10 Q&As (R4) Q8/Q9/Q10 – Implementation

Q10 Pharmaceutical Quality System

Q10 Pharmaceutical Quality System

Q8/9/10 Q&As (R4) Q8/Q9/Q10 – Implementation

Q11 Development and Manufacture of Drug Substances

Q11 Development and Manufacture of Drug Substances (Chemical Entities and Biotechnological/Biological Entities)

Q11 Q&As Questions & Answers: Selection and Justification of Starting Materials for the Manufacture of Drug Substances

Q12 Lifecycle Management

Q12 Technical and Regulatory Considerations for Pharmaceutical Product Lifecycle Management

Q12 IWG Training on Regulatory and Technical Considerations for Pharmaceutical Product Lifecycle Management

Q13 Continuous Manufacturing of Drug Substances and Drug Products

Q13 EWG Continuous Manufacturing of Drug Substances and Drug Products

Q14 Analytical Procedure Development Q2(R2)/Q14 EWG Analytical Procedure Development and Revision of Q2 (R1) Analytical Validation

Reference: ICH.org

References:

1. WHO GMP Guidelines: Guide to Master Formulae, WHO/FWC/IVB/QSS/VQR, 2011

EU and PIC GMP guidelines: EudraLex Volume 4, Chapter 4: Documentation

PIC/S guidelines: Chapter 4: Documentation

Health Canada GMP guidelines: Good manufacturing practices guide for drug products (GUI-0001), Manufacturing control, C.02.011

U.S. FDA: CFR 21, Chapter I, Subchapter F: Biologics, Part 211 Current Good Manufacturing Practice for Finished Pharmaceuticals; Subpart F–Production and Process Controls, Sec. 211.100 Written procedures; deviations; and Subpart J–Records and Reports; Sec. 211.186 Master production and control records

U.S. FDA: CFR 21, Chapter I, Subchapter F: Biologics; Subchapter C: Drugs General; Part 211 Current Good Manufacturing Practice for Finished Pharmaceuticals; Subpart J– Records and Reports; Sec. 211.188 Batch production and control records.

India: The drugs and cosmetics act, 1940 and The drugs and cosmetics rules, 1945, Schedule M, 12. Documentation and records]

2. PART 314 — APPLICATIONS FOR FDA APPROVAL TO MARKET A NEW DRUG, Subpart A – General Provisions Sec. 314.3 Definitions.

3. 21 CFR PART 210: CURRENT GOOD MANUFACTURING PRACTICE IN MANUFACTURING, PROCESSING, PACKING, OR HOLDING OF DRUGS; GENERAL Sec. 210.1 Status of current good manufacturing practice regulations.

5. Wet Granulation:

End-Point Determination and Scale-Up, By Michael Levin, Ph. D., Metropolitan Computing Corporation East Hanover, New Jersey, USA

6. Saudi Pharmaceutical Journal

Volume 20, Issue 1, January 2012, Pages 9-19, Saudi Pharmaceutical Journal, Review article, Upgrading wet granulation monitoring from hand squeeze test to mixing torque rheometry Author links open overlay panel Walid F. Sakr Mohamed A. Ibrahim Fars K. Alanazi Adel A. Sakr

7. natoli.com

8. pacifictools.in

160+ Pharmaceutical Interview Questions and Answers for Oral Solid Formulations

This page covers most of the interview questions and answers during a technical round in Production Oral Solid Dosage. The interview questions cover questions from basic to advance level of technical aspects. These interview questions and answers will help to crack an interview, enhance your knowledge, and also be helpful for the interviewer who is involved in the recruitment process.

The topics covered here are the Granulation process, the Tablet Compression process, the Coating process, and associated topics. In addition, the interview questions and answers cover various equipment used for the manufacturing process of solid oral formulation such as Compression Machine, Coating Machine, Graduation equipment, and supporting accessories.

You will find it much more enjoyable while going through these interview questions and answers. So enjoy learning, and best of luck with your interview! Happy Learning.

1. What is the granulation end point?

End-point can be defined by the formulator as a target particle size mean or distribution. [Reference: 5]

The agglomerate growth in wet granulation processes depend mainly on rheology of the wet powder mass, as an adequate consistency is necessary for a controllable coalescence and growth of smaller agglomerates into larger agglomerates.[Reference: 6]

2. Method for end point detection for wet granulation process.

i. Banana breaking test or Hand squeeze test

ii. Ampere load method

iii. Measurements of power consumption of the mixer motor

iv. Impeller Torque

v. Binder solution addition and measurement of Loss On Drying (LOD)

vi. Torque value

3. What is the Banana breaking method or Hand squeeze test for determination of granulation end point?

Wear hand gloves, take one handful of wet mass in the palm and press to make a lump. Open the palm and break the lump by pressing the thumb at the center of the lump.

4. What is the principle of metal detectors?

The operation of these metal detectors is based on the principles of electromagnetic induction. Metal detectors contain one or more inductor coils that are used to interact with metallic elements. Metallic contaminant in the product creates a high frequency magnetic field within the detector coil, which in turn activates a reject flap.

5. What is the fail safe mechanism of metal detectors?

When a metal detector gets off because of power failure or inadvertently did not start before the start of the batch, the flap should remain open so that tablets get rejected. It must be challenged at regular intervals (e.g.: start, intermittently and at the end of shift) to make sure they are effective.

6. What are typical standards used for the challenge of metal detectors?

Tablet: Ferrous – 0.3 mm, Non-ferrous – 0.3 mm, Stainless Steel – 0.5 mm, Plain (without metal as a blank)

Capsule: Ferrous – 0.1 mm, Non-ferrous – 0.15 mm, Stainless Steel – 0.2 mm, Plain (without metal as a blank)

7. What is tablet tooling?

Tooling consists of three parts.

i. Upper punch, ii. Lower punch, and iii. Die

8. What is the meaning of one set of tablet tooling?

One set consists of one Upper punch, one Lower punch and a Die.

9. What is a tooling station?

The place where one set accommodates the tablet press.

10. Explain parts of tablet tooling.

Punch terminologies:

Head: Head is the top part of upper and lower punch which contacts the machine’s cams and the pressure rollers apply the pressure to the head to compress the tablets.

Head flat or Dwell Flat: Top flat area of the head. Compression force applied through the upper punch head flat and ejection pressure applied through the head flat of lower punches. Dwell time for compression is determined based on the Head flat hence, it is also called Dwell Flat.

Outside head angle: The area touches the pressure roller during compression operation.

Inside head angle: The part of the punch head helps the upper punch to lift after compression of tablets and helps in pulling down the lower punches after ejection.

Neck: The part between head and barrel. Allow a clear path to the cam.

Barrel: Allows punch to do vertical up and down movement.

Stem: Area from tip end to barrel edge.

Tip: It is the lowest portion of the punch which is responsible for shape, size and profile of the tablet.

Tip face or cup: Outer part of the tip which gives shape to the tablet. The face also will have embossing depending on the need of the tablet requirement.

Tip length: The straight portion of the stem or tip.

Tip straight: The portion of tip towards the face having a higher diameter of the tip.

Tip relief: Tip part other than the tip straight.

Working length: This is the distance from the head flat to bottom of the cup.

Overall length: Length from punch head flat to the tip.

Key or woodruff key: An elevated portion in the middle of the punch barrel. The key with upper punches for shaped tablets to prevent punch rotation when the punch is out of the die.

Types of heads: Domed head and Flat head

Difference between Flat head and Domed head – Domed head punches have smaller flat heads.

The extended head flat offers multiple benefits, including a longer dwell time (the time the head flat spends in contact with the pressure roll) at a given press speed to better compact poorly compressible products. The longer dwell time may even reduce the amount of force required to attain specific tablet hardness.

Whereas, round extended head flats don’t require keyed tooling as oval ones do, and that allows them to be used on multiple makes and models of tablet presses.

Dwell time: It is the time the head flat spends in contact with the pressure roller.

Land: The area between the outer part of the punch cup and the outside edge of the punch tip.

Cup depth: Distance between tip edge to the center point of the cup.

Barrel chamfer: Chamfers at the ends of the punch barrel.

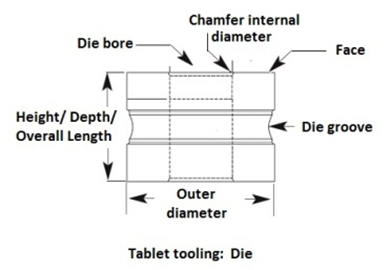

Die terminologies:

Clearance: pace between die bore diameter and punch tip diameter

Die Bore: It is the cavity of the die where granules are converted into tablets.

Die height or overall length: The height from top to bottom face of the die.

Die chamfer: This is the angle of the die bore at entry point. It guides the upper punch into the die bore.

Die groove and die lock: The radial groove around the die outer diameter requires locking the die into the turret with the help of die lock.

Die taper: Taper is a feature that increases the bore size at the top of the die then nominal bore size. It helps to release air from the die cavity during the compression. The feature helps to reduce tablet defects, such as capping and lamination.

Annealing: This is a heat treatment process to reduce the hardness to make it more workable. The processing done fragile punch tips to decrease the hardness of the punch cups which helps in reducing punch tip fracturing.

11. Describe tablet tooling standards?

There are two types of standards for tablet tooling:

i. US specification provided by Tableting Specification Manual (TSM) (This is the only tooling specifications are the only published standards for the tablet compression industry). The standard is established by the American Pharmacists Association (APhA),

ii. European standard known as the EU, or “Euronorm” standard.

EU, or Euronorm standard tool configurations are not published or governed by an organization or association. The EU standard is the most common tooling configuration used outside the U.S. [Reference: 7]

12. Differences between TSM and EU Tooling Configurations

| Tableting Specification Manual (TSM) Tooling Configurations | EU Tooling Configurations |

| Angled top profile | Domed head profile |

| Inside head angle for “B” punches is 37° | Inside head angle for “B” punches is 30° |

| Overall head thickness is greater in both “B” and “D” | Overall head thickness is lesser in both “B” and “D” |

| Overall punch length of the TSM tool is 0.010 inches shorter than the EU | Overall punch length of the EU tool is 0.010 inches longer than the TSM |

13. What is the type of tablet tooling for a compression machine with die and punch dimension?

There are the following six types of tablet tooling and its dimensions.

Tooling specification | Nominal punch barrel diameter (mm) | Nominal punch die diameter (mm) | Maximum tablet diameter for round tablet (mm) | Maximum tablet diameter for shaped tablet (mm) |

| TSM or EU B | 19 | 30.16 | 16 | 16 |

| TSM or EU D | 25.35 | 38.1 | 25 | 25 |

| TSM or EU BB | 19 | 24 | 13 | 14 |

| TSM or EU DB | 25.35 | 30.16 | 19 | 19 |

| TSM or EU BBS | 19 | 21 | 12 | 13 |

| TSM or EU A | 12.7 | 17 | 8 | 8 |

14. What is the choice for material of construction (MoC) of Die and Punch?

i. OHNS (T) Oil Hardened Non shrinking steel (Tungsten) – AISI 01 (American Iron and Steel Institute)

ii. HCHC – High carbon High chromium steel – AISI D3

15. What is the choice for material of construction (MoC) of Turret?

Three piece turret having the center die table of SS 316 and the Upper and lower piece of Spheroidal Graphite Iron (SG Iron) with ELNP (ELECTROLESS NICKEL PLATING) Coating.

16. What is the chemical composition of OHNS steel?

| Element | Content (%) |

| C | 0.85-1.00 |

| Si | 0.15-0.35 |

| Mn | 1.00-1.20 |

| P | 0.03 Max |

| S | 0.03 Max |

| Cr | 0.50-0.70 |

| W | 0.50-0.70 |

17. How much is the lifespan of the die and punches?

The life span of punches and dies is purely depending on materials of construction (MoC) as well as usage and handling.

OHNS Punches and HCHC Dies: 4 million tablets

HCHC Punches and HCHC Dies: 8 Million tablets Complete hard chrome plating punches and

HCHC dies: 10 Million tablets

18. How to maintain Punches and Dies?

The maintenance of compression tooling becomes easy by following these mentioned steps:

Step 1: Cleaning during every product change over or on a periodic basis. They can be wiped with IPA and dried using a lint free cloth.

Step 2: Periodic evaluation to increase their shelf life. Industry practice is to

Step 3: The regular visual inspection of the tooling should be done after each cleaning to check for physical damages to head, tip, die, and embossing, debossing using Magnifying glass.

Step 4: Periodic inspection of the punch set should be done using measuring tools. Frequency for die and punch inspection should be such that first inspection after procurement should be done after 3 million tablet compression using each tool set and subsequently after each million.

Step 5: Compression punch set should be lubricated to decrease friction and enhance the operational activity of the tablet compression machine. A non-toxic, FDA approved oils and greases should be used for preservation and lubrication purposes. Storage of tooling should be done in the safe and moisture-free place.

19. What should be available in a punch set/ tablet tooling inspection kit?

| 1 | Dial gauge compactor stand with a least count of 0.001 inch |

| 2 | Micrometer Range from 0.25 mm with least count : 0.01 mm |

| 3 | Punch holding bushes for B type punch and D type of punch |

| 4 | Punch height gauge |

| 5 | Die Outer diameter block for all types of die i.e. D, B, BB, DB etc. |

| 6 | Magnetic V – block |

| 7 | GO – NO GO gauges |

| 8 | Magnifying Glass |

| 9 | Die Pocket Cleaner |

20. Explain about the punch set/ tablet tooling inspection program?

i. Height uniformity of the punches

ii. Punch body to punch tip concentricity

iii. Die bore Go / No go status

iv. Other dimensions as per the drawing

v. Punch tip to die before clearance

vi. Hollow penetration of the punches

vii. Die outdoor diameter consistency

viii. Die height regularity

ix. Die hole GO and NO GO examination

x. Die internal diameter to outer diameter concentricity

21. Issue that may arise after prolonged use for punch set/ tablet tooling.

i. Tablet weight difference

ii. Tablet hardness difference

iii. Powder leakage from lower punch or collar formation

iv. Twisting of small size punch tips

22. Commonly used material of construction in the pharmaceutical industry for equipment manufacturing?

i. Commonly used materials of construction in the pharmaceutical industry for product contact parts are Stainless steel 316, 316 L, Toughened glass, Silicon, Food grade Teflon etc.

ii. Commonly used materials of construction in the pharmaceutical industry for non-product contact parts are Stainless steel 304, 304 L, Teflon, Anodized or powder coated aluminum, brass etc.

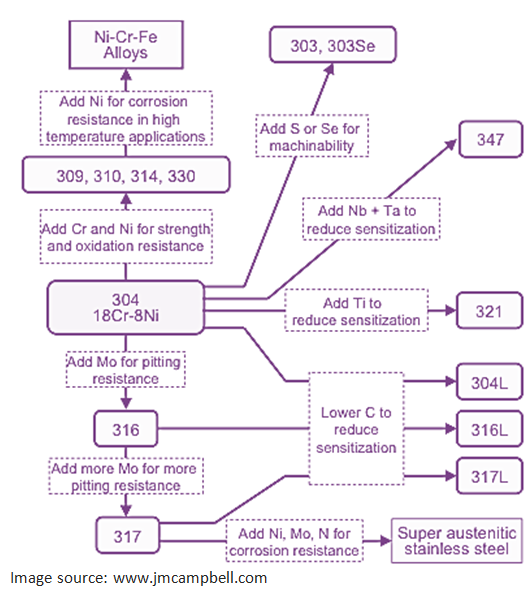

23. Explain characteristics of different grades of stainless steel material.

Following are the different types of types of Stainless and similar material with its characteristics.

| Stainless and similar material | Application for the different types of environment |

| Hastelloy C276 | Excellent corrosion resistance in a wide range of severe environments |

| 316, 316L | Chemical corrosion |

| 304, Custom 450 | Medium Corrosion |

| 430, 431, Custom 455 | Industry polluted air |

| 405, 410, 420, 440 | Clean air |

24. Explain most commonly used stainless steel for pharmaceutical industry and its attributes.

Following most commonly used stainless steel for the pharmaceutical industry and its attributes.

| Commonly known names | UNS | EN | Attributes |

| 304 | S30400 | 1.4301 | Good at general corrosion resistance to acidic as well as caustic material |

| 304L | S30403 | 1.4307 | Good at general corrosion resistance to acidic as well as caustic material with low carbon and improved performance |

| 316 | S31600 | 1.4401/ 1.4436 | Improved corrosion resistance to most acidic as well as caustic material with high temperature or chloride present |

| 316L | S31603 | 1.4404/ 1.4432 | Improved corrosion resistance to most acidic as well as caustic material with high temperature or chloride present with low carbon and improved performance |

25. How to distinguish SS 202, SS 304 and SS 316 grade stainless steel?

Using molybdenum detection electrolyte kit. To know how to perform the test, Click Here.

26. What is the composition of SS 304, SS 304L, SS 316, and SS 316L?

Following are the composition of SS 304, SS 304L, SS 316, and SS 316L

27. What is the meaning of Suffix L in SS 316L and SS 304L?

Suffix L for SS 316 and SS 304 represents low carbon content. Standard grade consists of ≤ 0.08 % carbon and low carbon grade consists of ≤ 0.03 % carbon content.

28. What are the different types of stainless steel in terms of material composition?

29. What is Hastelloy?

Hastelloy is a nickel-molybdenum-chromium superalloy with an addition of tungsten designed to have excellent corrosion resistance in a wide range of severe environments. The high nickel and molybdenum contents make the nickel steel alloy especially resistant to pitting and crevice corrosion in reducing environments while chromium conveys resistance to oxidizing media. The low carbon content minimizes carbide precipitation during welding to maintain corrosion resistance in as-welded structures. This nickel alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process application in an as welded condition.

Source: megamex.com

30. In what applications is Hastelloy used?

i. Pharmaceutical and food processing equipment

ii. Chemical processing components like heat exchangers, reaction vessels, evaporators, and transfer piping

iii. Sour gas wells

iv. Waste treatment

31. Which are typical in-process control tests for tablets?

Dimensions

Hardness

Friability

Thickness

Disintegration

Weight variation

Content uniformity

Dissolution

Leakage testing for strip and blister packaging

Checking printing matter during packaging

Physical appearance of packs

32. Explain Disintegration time (DT) of different types of tablets?

Disintegration time (DT) of different types of tablets is as follows.

| Types of tablets | Disintegration time (DT) |

| Uncoated | 15 minutes |

| Plain coated tablet | 60 minutes |

| Enteric coated tablet | 3 hours |

| Dispersible tablet | 3 minutes |

| Effervescent tablet | ˂ 3 minutes |

| Sublingual tablet | 4 hours |

| Buccal tablet | 4 hours |

| Vaginal tablet | 60 minutes |

| Chewable tablet | not required |

33. What are the types of hardness testers?

Manual hardness tester

Monsanto tester

Pfizer tester

Strong-cobb

Automatic hardness testers

Erweka tester

Dr. Schleuniger tester

34. Which instruments are used for testing tablet dimension?

A. Vernier caliper

1. Outside jaws: used to measure external length

2. Inside jaws: used to measure internal length

3. Depth probe: used to measure depth

4. Main scale (cm)

5. Main scale (inch)

6. Vernier (cm)

7. Vernier (inch)

8. Retainer: used to block/release movable part

B. Micrometer screw gauge

35. Which instruments are used for testing of tablet friability?

Roche friabilator is used for testing of tablet friability.

36. Explain the construction of tablet friability tester, testing process and limit.

i. Plastic chamber that revolves at 25 rpm

ii. For testing it operates for 100 revolutions

iii. Dropping the tablets from a Distance of 6 inches in the tester

iv. The tablets are weighed before and after rotation. De-dust tablets after rotation. Perform calculation in percentage weight loss.

v. Limit of friability testing is NMT 1.0 %

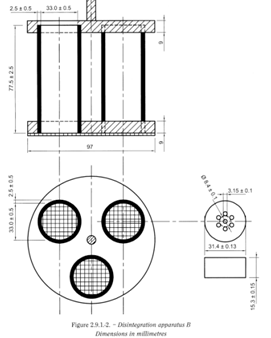

37. What is Disintegration Time (DT) Test?

Disintegration time is time taken to break down the tablets into granules or primary powder particles.

38. Explain the tablet disintegration tester parts.

i. Basket rack assembly

ii. A suitable vessel for the immersion liquid

iii. Heater for fluid heating between 35°C and 39°C

iv. Basket in the immersion in fluid at frequency rate between 28 and 32 cpm (Cycle per minute)

v. Distance of up and down not less than 5 cm and not more than 6 cm

39. What are the common tablet defects at compression stage?

Weight variation

High friability

High or low hardness (resistance to crushing)

Sticking

Picking

Capping

Laminating

Chipping

Mottling

Double press or impression

Cracking

Binding

Edging or Flashing of tablet

Disintegration time abnormality

Black Spot/ particles/ fiber

Improper embossing or debossing

Layer separation

Improper Layers

40. What are the different types of tablet coating defects?

Blistering

Chipping

Cratering

Sticking or Picking

Pitting

Blooming

Blushing

Color Variation

Infilling

Orange Peel or Roughness

Cracking or Splitting

Twinning Erosion

Bridging

41. Definitions of tablet defects at compression stage.

Weight variation: Individual weight of tablet outside of the accepted criteria.

High friability: The condition of tablets being friable. The tendency of tablets to break into smaller pieces or weight loss of powder from the surface of the tablets due to mechanical action such as transportation conditions. When percentage loss is more than 1%, it is considered as high friability.

To view images of tablet defects and to download high resolution poster, CLICK HERE

High or low hardness (resistance to crushing): Individual hardness of tablets is outside the accepted limit (upper limit or lower limit). Hardness limits are determined during the development phase of the product.

Sticking: Sticking is a defect of the tablet wherein the portion tablet surface sticks to the face of the punch or to the die wall during tablet compression activity.

Picking: Picking is a counter part of the sticking. When part of the tablet surface sticks to the punch or to the die wall, the produced tablets are with a pitted surface instead of a smooth surface.

Capping: Capping (or splitting) is a term used to describe the partial or complete separation of the upper or lower segment of the tablet horizontally from the main body of a tablet during ejection from the tablet press.

Laminating: Laminating of tablets means separation of a tablet into two or more different parallel layers.

Chipping: Chipping of tablets is the breaking of tablet edges during manufacturing or handling.

Mottling: Mottling of tablet refers to unequal or nonuniform distribution of color on the tablet surface.

Double press or impression: Double impression is a tablet defect where an embossing or break or score line appears two times on the tablet surface.

Cracking: Cracking of tablets means small fine cracks on the upper and lower central surface of the tablets and sometimes seen on the side wall.

Binding: The term binding is used when tablets stick to the die and do not eject properly out of the die.

Edging or Flashing of tablet: Edging or Flashing means observation of burrs or sharp edges on the edges of tablet.

Disintegration time abnormality – Too fast or too slow disintegration of tablets.

Black Spot/ particles/ fiber – Observation of black spot or particles or fiber which could be indigenous or foreign matter or contaminant.

Improper embossing or debossing: The defect because of improper embossing or debossing of letter, logo or monogram.

Layer separation: Layer separation is the defect of a tablet where layers of tablet get separated. This is usually seen in tablets such as bilayer tablets.

Improper Layers: Improper Layers mainly appear in layered tablets such as bilayer tablets. In this type of defect, the layer does not distinguish sharply.

42. What are the different types of tablet coating defects?

Blistering: Blistering means blistering of a surface film appears when film becomes detached from the tablet’s substrate.

Chipping: Chipping means dented and chipped film mostly on the edges of the tablet.

Cratering: Cratering means volcanic-like cratering happens exposing the tablet surface.

Sticking or Picking: Sticking or picking means sticking of film with each other or with the coating pan resulting in some of the tablet pieces being detached from the core.

Pitting: Pitting is the deformation of the core of the tablet without any visible signs of disruption of the film coating.

Blooming: Blooming is the fading or dulling of a tablet color after it is stored for a prolonged period at a high temperature.

Blushing: Blushing is described as the appearance of white specks or a haziness in the film.

Color Variation: Color variation of tablet film.

Infilling: This refers to the filling of intagliations – i.e., the distinctive words or symbols formed on the tablet.

Orange Peel or Roughness: When film having a rough surface or having a matt surface rather than glossy texture. It appears the same as an orange.

Cracking or Splitting: The cracking defect is observed when the film coating of the tablet cracks in the crown area or splits around the edges.

Twinning: Twinning is when two tablets stick together.

Erosion: Coating gets removed from the surface due to friction between tablets.

Bridging: When coating material fills in the logo or letter, bridging occurs.

43. Explain the remediation for various types of tablet defects.

44. What are the different sizes of hard gelatin capsules?

The capsule sizes are 000, 00, 0, 1, 2, 3, 4, and 5 from the largest to the smallest. There are few special sizes of capsules available such as 2el, 1el, 0el, 0el+, 0xel, 00el etc. Details are tabulated below.

45. What are the US Mesh size and corresponding micron, mm and inch for commonly used sieves, provide a few examples?

| U.S. Mesh | Microns | Inches | Millimeters |

| 3 | 6730 | 0.2650 | 6.730 |

| 4 | 4760 | 0.1879 | 4.760 |

| 5 | 4000 | 0.1570 | 4.000 |

| 6 | 3360 | 0.1320 | 3.360 |

| 7 | 2830 | 0.1110 | 2.830 |

| 8 | 2380 | 0.0937 | 2.380 |

| 10 | 2000 | 0.0787 | 2.000 |

| 12 | 1680 | 0.0661 | 1.680 |

| 14 | 1410 | 0.0555 | 1.410 |

| 16 | 1190 | 0.0469 | 1.190 |

| 18 | 1000 | 0.0394 | 1.000 |

| 20 | 840 | 0.0311 | 0.841 |

| 25 | 707 | 0.0280 | 0.707 |

| 30 | 595 | 0.0232 | 0.595 |

| 35 | 500 | 0.0197 | 0.500 |

| 40 | 400 | 0.0165 | 0.400 |

| 45 | 354 | 0.0138 | 0.354 |

| 50 | 297 | 0.0117 | 0.297 |

| 60 | 250 | 0.0098 | 0.250 |

| 70 | 210 | 0.0083 | 0.210 |

| 80 | 177 | 0.007 | 0.177 |

| 100 | 149 | 0.0059 | 0.149 |

| 120 | 125 | 0.0049 | 0.125 |

| 140 | 105 | 0.0041 | 0.105 |

| 170 | 88 | 0.0035 | 0.088 |

| 200 | 74 | 0.0029 | 0.074 |

| 230 | 63 | 0.0024 | 0.063 |

| 270 | 53 | 0.0021 | 0.053 |

| 325 | 44 | 0.0017 | 0.044 |

| 400 | 37 | 0.0015 | 0.037 |

| 450 | 32 | 0.0013 | 0.032 |

| 500 | 25 | 0.0010 | 0.025 |

| 550 | 25 | 0.0009 | 0.023 |

| 635 | 20 | 0.0008 | 0.020 |

| 800 | 15 | 0.0006 | 0.015 |

| 1250 | 10 | 0.0004 | 0.010 |

Reference: ASTM E11

46. Give examples of sieve size and corresponding number of Apertures per Linear inch.

| Sr. No. | Sieve Size | Number of Apertures per Linear Inch |

| 1 | 10 # | 9-11 |

| 2 | 12# | 11-13 |

| 3 | 14# | 13-15 |

| 4 | 16# | 15-17 |

| 5 | 20# | 19-21 |

| 6 | 24# | 23-25 |

| 7 | 30# | 28-32 |

| 8 | 40# | 38-42 |

| 9 | 60# | 57-63 |

| 10 | 80# | 77-83 |

| 11 | 100# | 97-103 |

47. What is the aperture size of the screen?

The size of a square opening (length of clear space between individual wires) is called the aperture size of the screen.

48. What is the Mesh number of screens?

Mesh number of screens is defined as the number of aperture or opening per linear inch of the screen. E.g. A screen having 10 square openings per inch is said to have Mesh no. 10. Higher the mesh number, smaller the aperture size of the screen.

49. What is the broad classification of Granulation techniques?

Granulation technique is broadly classified into two types as follows:

(i) Dry granulation

a. Slugging technique

b. Roller compaction

c. Pneumatic dry granulation

(ii) Wet granulation

a. Steam granulation

b. Reverse wet granulation

c. Moisture-Activated Dry Granulation

d. Thermal adhesion granulation

e. Melt granulation

f. Freeze granulation

g. Foam granulation

50. What are the equipment used during the Wet Granulation Process?

Depending on process, batch size and type of process steps, following equipment are used during the Wet Granulation Process.

Low Shear mixer/ granulator

High Shear mixer/ granulator OR Rapid Mixture granulator

Fluid-Bed granulator/ dryer,

Spray Dryer,

Extruders and Spheronizer

Vibratory sifter

Cutting mills such as Multimill, Co-mill, Pin Mill etc.

Hammer mill

51. What are the equipment used during the Dry Granulation Process?

Depending on process, batch size and type of process steps, following equipment are used during the Dry Granulation Process.

Role com

Low Shear mixer/ granulator

High Shear mixer/ granulator OR Rapid Mixture granulator

Vibratory sifter

Cutting mills such as Multimill, Co-mill, Pin Mill etc.

Roller Compactor Granulator

Compression machine to generate slugs

52. What is the most commonly used testing method to determine powder flow?

There are four commonly used methods for testing powder flow:

(1) Angle of repose

(2) Compressibility index or Hausner ratio

(3) Flow rate through an orifice

(4) Shear cell

Reference: General Chapters: <1174> POWDER FLOW

53. What is Angle of Repose?

Definition of Angle of Repose: The angle of repose is a relatively simple technique for estimating the flow properties of a powder. It is determined by allowing a powder to flow through a funnel and fall freely onto a fixed diameter base. The height and diameter of the resulting cone are measured. For further reading on Angle of Repose and download free excel, click on this link.

54. What is the Compressibility index and what is Hausner Ratio?

Definition of Compressibility index: The Compressibility Index (Carr Compressibility Index) is a measure of the tendency of a powder to be compressed. It is a measure of the powder’s ability to settle, and it permits an assessment of the relative importance of interparticulate interactions.

Definition of Hausner Ratio: The Hausner Ratio is measures that can be used to predict the tendency of a given powder sample to be compressed. Hausner Ratio reflects the importance of interparticulate interactions.

55. What is the disintegration time of Chewable Tablets?

Disintegration time test is not applicable for chewable tablets.

56. What is the standard number of rotations used for friability test?

100 Revolutions / 4 Minutes, 25 rotations per minute

57. What is the fall height of the tablets in the friabilator during friability testing?

Fall height of the tablets is in the friabilator is 154.0 – 158.0 mm (156.0 ± 2.0 mm)

58. Which capsule is bigger in size – size ‘0’ or size ‘1’?

‘0’ size

59. How many tablets shall be taken for checking friability?

6.5 g for the tablets with unit mass equal or less than 650 mg. For tablets with unit mass more than 650 mg, it requires 10 tablets.

60. What is the mesh aperture of DT apparatus?

Mesh aperture of DT apparatus is #10. That is 1.8 -2.2 mm.

61. What is the standard frequency of upward and downward movement of a basket-rack assembly in a DT apparatus?

28 – 32 cycles/minute

62. What are the parameters tested during the calibrating DT apparatus?

Parameters covered during the DT apparatus calibration are as follows

(1) Number of strokes per minute (Limit: 29-32 cycles/min)

(2) Temperature by probe and standard thermometer (Limit: 37 ± 1 °C). (3) Distance travelled by basket (Limit: 53 -57 mm)

63. What is the Disintegration time for different types of tablets?

| Type of Tablets | Disintegration time |

| Uncoated Tablets | 15 minutes |

| Film-coated | 30 minutes |

| Other coated tablets | 60 minutes |

| Enteric-coated Tablets | |

| 0.1M hydrochloric acid | Should not disintegrate in 120 minutes |

| Phosphate buffer pH 6.8, | 60 minutes. |

| Dispersible and Soluble Tablets | within 3 minutes |

| Effervescent Tablets | 5 minutes |

| Chewable tablets | Not applicable |

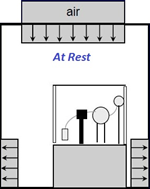

64. What are the different clean room conditions? Explain it.

There are three conditions of clean rooms – as built, at rest and in-operation.

As built:

Condition where the installation is complete with all services connected and functioning but with no production equipment, materials, or personnel present.

At rest:

Condition where the installation is complete with equipment installed and operating in a manner agreed upon by the customer and supplier, but with no personnel present.

In operational:

This condition relates to carrying out room classification tests with the normal production process with equipment in operation, and the normal staff present in the room.

Reference: WHO Working document QAS/02.048/Rev.2

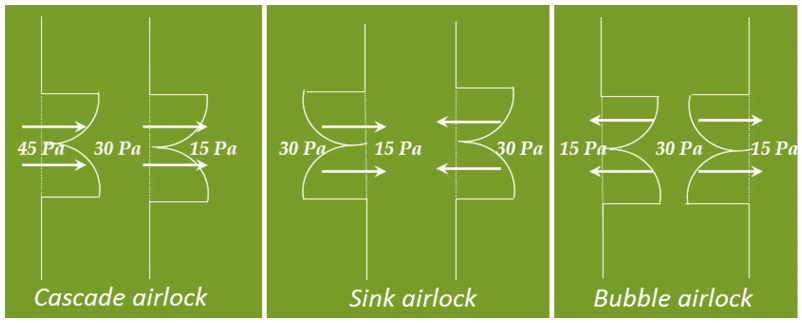

65. What are the different types of air locks? Explain it.

There are three types of air locks, Cascade airlock, Sink airlock and Bubble airlock.

Cascade airlock: high pressure on one side of the airlock and low pressure on the other side.

Bubble Airlock: high pressure inside the airlock and low pressure on both outer sides.

Sink Airlock: low pressure inside the airlock and high pressure on both outer sides.

Reference: WHO Working document QAS/02.048/Rev.2

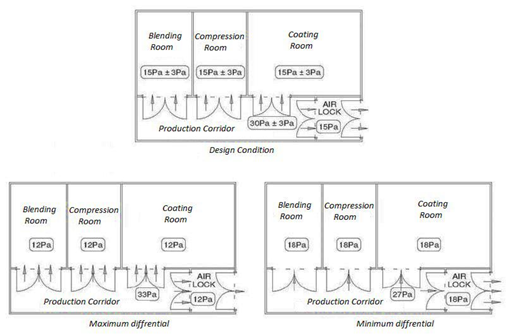

66. What should be the differential pressure between two adjacent clean room zones?

The most widely accepted pressure differential to achieve containment between the two adjacent zones is 15 Pa, but pressure differentials of between 5 Pa and 20 Pa could be acceptable.

Where the design pressure differential is too low and tolerances are at opposite extremities, a flow reversal can take place. E.g. where a control tolerance of ±3 Pa is specified, the implications of the upper and lower tolerances on containment should be evaluated.

67. Comparison of pascals to mm of water?

Pascals to Millimeters of water formula

mm H2O =Pa * 0.10197

Pascals (Pa)

Millimeters of water (mm H2O)

| Pascals | Millimeters of water | Pascals | Millimeters of water | Pascals | Millimeters of water |

| 1Pa | 0.10mm H2O | 16Pa | 1.63mm H2O | 31Pa | 3.16mm H2O |

| 2Pa | 0.20mm H2O | 17Pa | 1.73mm H2O | 32Pa | 3.26mm H2O |

| 3Pa | 0.31mm H2O | 18Pa | 1.84mm H2O | 33Pa | 3.37mm H2O |

| 4Pa | 0.41mm H2O | 19Pa | 1.94mm H2O | 34Pa | 3.47mm H2O |

| 5Pa | 0.51mm H2O | 20Pa | 2.04mm H2O | 35Pa | 3.57mm H2O |

| 6Pa | 0.61mm H2O | 21Pa | 2.14mm H2O | 36Pa | 3.67mm H2O |

| 7Pa | 0.71mm H2O | 22Pa | 2.24mm H2O | 37Pa | 3.77mm H2O |

| 8Pa | 0.82mm H2O | 23Pa | 2.35mm H2O | 38Pa | 3.87mm H2O |

| 9Pa | 0.92mm H2O | 24Pa | 2.45mm H2O | 39Pa | 3.98mm H2O |

| 10Pa | 1.02mm H2O | 25Pa | 2.55mm H2O | 40Pa | 4.08mm H2O |

| 11Pa | 1.12mm H2O | 26Pa | 2.65mm H2O | 41Pa | 4.18mm H2O |

| 12Pa | 1.22mm H2O | 27Pa | 2.75mm H2O | 42Pa | 4.28mm H2O |

| 13Pa | 1.33mm H2O | 28Pa | 2.86mm H2O | 43Pa | 4.38mm H2O |

| 14Pa | 1.43mm H2O | 29Pa | 2.96mm H2O | 44Pa | 4.49mm H2O |

| 15Pa | 1.53mm H2O | 30Pa | 3.06mm H2O | 45Pa | 4.59mm H2O |

68. What is the difference between disintegration and dissolution?

Disintegration is a process of breaking down of granules into small fragments.

Dissolution is the process in which a substance goes into a solution. It is a measure of bioavailability and therapeutic effectiveness. Dissolution is also called drug release.

69. What is the purpose of maintaining pressure gradients between processing areas and service corridors?

Pressure gradients are maintained to avoid cross contamination of products through air.

70. In oral solid manufacturing facility ‘positive’ pressure is maintained in processing area or in service corridors?

Positive pressure is maintained in service corridors with respect to processing rooms.

71. What should be the characteristic of Finger Bags used for Fluid Bed Dryer (FBD) or Fluid Bed Processor (FBP)?

Antistatic

Waterproof cloth

Able to handle granulation of highly viscous materials, such as extract powder

Non-stick cloth bag

Good permeability

Good boiling effect

Cost-efficient and durable

72. What is generally used material of construction of Finger Bags used for Fluid Bed Dryer (FBD) or Fluid Bed Processor (FBP)

Finger bags are constructed by a combination of Antistatic polymer, Nylon fabric and Cotton fabric. Following materials are also used for Finger bags’ construction.

Antistatic

Epitropic

Polypropylene

Polyester

Stain

73. What are the typically seen micron ratings of Finger Bags used for Fluid Bed Dryer (FBD) or Fluid Bed Processor (FBP)?

Micron Rating: 1, 5, 10, 15, 25, 50, 100

74. What is the formula for calculating friability test results?

Friability (%) = Weight 1 – Weight 2 / Weight 1 X 100

Where,

Weight 1 = Weight of Tablets (Initial / Before Tumbling) & Weight 2 = Weight of Tablets (After Tumbling or friability)

75. What is the limit of friability test results?

Limit: Friability (%) = Not More Than 1.0 %

76. What is Rheology?

Rheology (Greek words rheos meaning flow and logos meaning science) is the study of the flow under the influence of stress. The principle can be applied to solids, liquids, and gases.

77. Explain the types of excipients.

Organoleptic

o Color

o Flavor

o Sweetener

Stabilizers

o Preservative

o Antioxidant

o Emulsifier

o Suspending Agent

Dose Accuracy

o Diluent

o Bulking agent

o Filler

Process Aids

o Binder

o Lubricant

o Glidant

o Anti-adherent

Drug release

o Disintigrant

o Penetration enhancer

o Coating agent

78 What are the types of tablets? Or Classification of Tablets.

Classification of tablets by route of administration

Oral tablets for ingestion

Implantation tablets

Chewable tablets

Tablets used in the oral cavity

Buccal and sublingual tablets

Dental cones

Vaginal tablets

Tablets used to prepare solutions

Effervescent tablets

Dispensing tablets (DT)

Hypodermic tablets (HT)

Tablet triturates (TT)

Troches and lozenges

Classification of tablets by manufacturing process

Compressed tablets

Layered tablets

Sugar coated tablets

Film-coated tablets

Classification of tablets by onset of action

Immediate release tablets

Repeat-action tablets

Delayed-action and enteric coated tablets Controlled release tablets

79. What are the various types of tablets?

Following are various types of tablets.

- Compressed Tablet (CT)

- Sugar-Coated Tablets (SCT)

- Film-Coated Tablets (FCT)

- Enteric-Coated Tablets (ECT)

- Multiple Compressed Tablets (MCT)

- Layered Tablets

- Press-Coated Tablets

- Controlled-Release Tablets (CRT)

- Tablets for Solution (CTS)

- Effervescent Tablets

- Compressed Suppositories or Inserts

- Buccal and Sublingual Tablets

- Molded Tablets or Tablet Triturates (TT)

- Dispensing Tablets (DT)

- Hypodermic Tablets (BT)

- Compressed Tablets (CT)

80. What are the ingredients used to formulate or manufacture the various types of tablets?

Following are ingredients used to formulate or manufacture the various types of tablets.

- Active pharmaceutical ingredient

- Diluents

- Binders

- Lubricants

- Glidants

- Disintegrants

- Coloring Agents

- Flavoring Agents

81. Explain parts of the compression machine.

- Machine Hopper

- Feeder System (force feeder/ gravity feeder)

- Feeder housing

- Feed pedals

- Punches System

- Upper punch system

- Lower punch system

- Die System

- Turret

- Machine Cam Tracks

- Powder Filling Station and Weight Control

- Compression Rollers (Pre-compression, main-compression)

- Tablet Press Ejection Cam

- Take –off blade

- Discharge Chute

- Touch Screen Control Panel (HMI/ MMI)

- Electric Motors, Gears and Belts

- Lubrication Systems

82. What are the types of tablet press or compression machines?

Broadly, we there are two main types of tableting machines:

- Single-station tablet press or compression

- Multi-station tablet press or compression

- Single rotary machine

- Double rotary machine

83. What are the types of tablet Coating Machines available in the market?

• Standard Coating Pan

• Perforated Coating Pan

• Fluidized Bed Coater

84. What are the advantages of the tablet coating process?

Following are the advantages of tablet coating:

• It enhances its appearance

• Easy to consume

• Minimizes the unpleasant colour, odour or taste of drug

• Identification

• Helps to reduces drug degradation by protecting it from environmental factors

• Facilitates the packing process

• Functional coating gives functional advantages like extended release, enteric release, prolonged release etc.

85. What are the disadvantages of the tablet coating process?

Following are the disadvantages of tablet coating:

• Cost of operation, resources and material

• Equipment operation and maintenance cost

• May change tablet properties

• Residual solvent toxicity

• Waiting time between processes

• Increase process lead time

• Increase analysis load

86. Explain parts of tablet coating equipment or machine.

Following are the parts of tablet coating equipment or machine

• Perforated coating pan

• Baffles in coating pan

• Spray gun

• Spray pump e.g. Peristalsis pump, Diaphragm pump

• Electric Motors

• Air Handling unit for inlet air

o Inlet air blower

o Air Handling unit housing

o Primary filter (Washable)

o High temperature HEPA filter

o Inlet air temperature sensor

o Differential air pressure sensors across the above filters

• Ducting to supply air and exhaust air

• Control panel with PLC Control and HMI

• Exhaust air blower

• Dust collector or air Scrubber (Wet or Dry)

• Solution preparation tank

87. Explain parts of Fluid bed dryer and Fluid bed processor?

Following are the parts of Fluid bed dryer and Fluid bed equipment

• Plenum

• Product Container with PU wheel trolley

• Inflatable gasket for connection between plenum and Product Container, and Product Container and expansion chamber

• Product temperature sensor

• Inlet air temperature and RH sensor

• Damper for inlet air

• Sample collection port in Product Container

• Glass view in Product Container

• Silicon molded Dutch Woven sieves

• Conidur mesh for mechanism of vortex formation

• Expansion chamber

• Glass view in Expansion chamber

• Finger bag

• Finger bag mounting assembly

• Finger bag shaking assembly

• Inflatable gasket to seal finger bag assembly

• Broken Bag Detector (BBD) sensor OR Solid Flow Monitor (SFM) sensor

• Exhaust blower

• Exhaust filters (10 and 3 µm porosity)

• Explosion flap and Explosion port

• Inlet Air Handling Unit

o Air Handling unit housing

o Primary filter (Washable)

o High temperature HEPA filter

o Dew point sensor

o Differential air pressure sensors across the above filters

o Damper

• CFM or Air flow sensor

• Inlet air duct

• Clean in place system

• Differential pressure sensors, across filters, across finger bag, across product container

• Exhaust air temperature

• Spraying system (for top spray granulation)

88. What is a Tablet Deduster?

Deduster is an equipment used in the pharmaceutical and nutraceutical industry to remove surface dust from the tablets.

89. What are different types of tablet Deduster?

- Rotary Vibrating Deduster

- Uphill Deduster

- Brush Type Deduster

- Horizontal Deduster

- Vertical Deduster

i. Vertical Downward Conveying Deduster

ii. Vertical Upward Conveying Deduster

90. Explain in detail about different types of Tablet Deduster.

There are different types of tablet dedusters. Each has its advantages and disadvantages.

a. Rotary Vibrating Tablet Deduster

Rotary Vibrating Tablet Deduster depends on rotation and vibration principles.

It has a vibrated helical path with a perforated sieve. As the tablets vibrate and spin along the helical path with a perforated plate, burrs and dust are wiped from their surface. A dust extraction mechanism extracts the dust and the tablets drop into the collection container.

b. Uphill Tablet Deduster

Uphill tablet Dedusting machine depends on the vibration that removes burr and dust as it elevates the tablets. The deduster elevates and dedusts concurrently.

c. Brush Type Tablet Deduster

It consists of a helically wound brush installed within a stainless steel tube (same as screw conveyor) steered by an adjustable speed motor.

The brush pushes the tablets across the tube till they get to the discharge of the deduster at the top or end.

d. Horizontal Tablet Deduster

These types of tablet dedusters use perforated tubes or perforated stainless steel plates that vibrate from one side to another. It is horizontal but slants downwards that the tablets fall as the vibration conveys them over a distance of around 1 meter.

e. Vertical Tablet Deduster

Vertical tablet dedusters are of two types, Downward Conveying Tablet Dedusters and Upward Conveying Tablet Dedusters. The working principle of both types of dedusters are similar.

The dedusters rely on spiral punctured trays on an anchored central column.

91. Which Material is used to make Tablet Dedusters?

Stainless Steel: Stainless steel forms the largest portion of tablet dedusters.

Acrylic: To make the windows.

92. Which Quality Standards should a Tablet Deduster Comply with?

a. Current good manufacturing practices (cGMP) quality standards

b. ISO certification quality standards

c. CCC compliant

d. CE certification

93. How do you select the tablet deduster?

a. Height of compression machine and containers

b. Tablet Size

c. Output

d. Tablet Hardness and Features of Dust

e. Inclusion of Extra Components such as metal detector

94. Explain parts of multimill?

Material Charging Hopper: To load the material to be milled

Milling chamber: Milling of material happens within the chamber with the help of Cutting blades and desired size of particles are passed through specific size screen

Discharge port: Milled material is discharged from this part

Castor wheels: To move the mill from one place to another place

Operating Panel: To operate the equipment

Screen: To produce desired particle size

Cutting blades: To mill the material

95. What is the Material Of Construction (MOC) of multimill parts?

Product contact parts are made up of SS 316 or SS316L

Non-product contact parts are made up of SS 304 Castor wheels are made up of Polyurethane

96. What is the mechanism of size reduction when using multimill?

a. Impact Milling: Particles are reduced in size by high-speed mechanical impact or impact with other particles; also known as milling, pulverizing, or comminuting.

b. Cutting: Particles are reduced in size by mechanical shearing.

c. Screening: Particles are reduced in size by mechanically induced attrition through a screen. This process commonly is referred to as milling or deagglomeration.

97. What are the typical speeds of multimill?

Fast speed: 2880

Medium fast speed: 2160

Medium speed: 1440

Low speed: 720

Note: Nowadays multimill are available with variable frequency drive where speed can be set as per the requirement (Custom speed).

98. What are the typical settings for milling operation using multimill?

Blade direction: Impact forward or Knife forward

Machine speed: Using V belt adjustment or using VFD as per machine design

99. What is Vibro sifter?

Vibro sifter is equipment used for separating particles based upon particle size alone and without any significant particle size reduction. This process commonly is referred to as screening or bolting. Vibration and Gyratory motion plays an important role to facilitate the screening process.

100. What is the principle of Vibro sifter?

Vibro sifters work on the principle of separation. Particles are segregated based upon particle size alone and without any significant particle size reduction. This process commonly is referred to as screening or bolting. Vibration and Gyratory motion plays an important role to facilitate the screening process.

The mechanism on which Vibro Sifter works is the principle of gyratory vibrations. The material is separated based on its particle size. Once the motor gets energized, vibration is caused in the screen/. This makes material travel across the sieves according to its particle size and sieve/ screen size.

Separator subclasses as per SUPAC: Vibratory/ Shaker and Centrifugal.

101. What is the gyratory motion of a vibro sifter and how does it get generated?

In the vibro sifter gyratory motion is obtained from a specially designed gyro motor, which is fitted underneath the vibrating assembly. A specially designed rugged spring completely isolates this assembly from the base with the help of Gyro-motor.

The motor is fitted with eccentric weights present at its top as well as base to create centrifugal force. This whole assembly is covered by an SS plate.

102. What are other names of vibro sifters?

The vibro sifter machine is also known as:

Vibro Screen

Vibrating Screen

Lab Vibro Sifter

Pharmaceutical Sifter

Vibro Sieve

Vibro Sifter Machine

Powder Sieving Machine

103. What are the salient features or use of vibro sifter?

• Gradation and separation of dry powder, granules, semi solids and liquids

• Main functioning mechanical arrangement is suspended on a spring to prevent vibration on the floor

• Easy assembling and disabling

• Easy to clean

104. What are different parts of vibro sifter?

• Dust cover

• Clamp for assembling of different parts

• Inlet

• Sieve/ screen

• Vibrating motor for Gyratory motion with eccentrically arranged top and bottom hammer

• Caster wheel

• Discharge port

• Spring

105. How to discharge the static electricity which may get generated over the vibro sifter sieve when silicone bonded sieve is used?

Following are the solutions to discharge the static electricity which may get generated over the vibro sifter sieve when silicone bonded screen is used:

i. Using antistatic screen

ii. Use C clamp over the silicone bonded sieve which makes the entire assembly conductive and to provide earthing to the body of the equipment.

106. What is a solution preparation vessel?

The solution preparation vessel is a closed tank used to prepare solution at room temperature or elevated temperature by using electrical heating or steam heating. To mix the solution homogeneously, it consists of stirring to create a vortex inside the solution.

107. What is the use of solution preparation vessels in the pharmaceutical industry?

The solution preparation vessel is used to prepare various types of solutions such as binder solution, coating solution, heating of water, liquid preparations such as syrup, suspension, solutions, etc. The vessel is used to ensure a homogeneous mix.

108. Explain parts of solution preparation vessel and Material of Construction (MOC)?

• Tank – SS316 or SS316L

• Stirrer – SS316 or SS316L

• Thermal Insulation

• Motor

• Variable Frequency Drive

• Control Panel

• Pressure gauge for jacket

• Temperature sensor – Product contact part SS316 or SS316 L

• Discharge valve (Zero dead leg and sanitary type)(Note: Ball valve is not acceptable) – SS316 or SS316L

• Caster wheel for movement (Need based) – Polyurethane

109. What is vortex and how is it helpful for solution preparation?

A circular, spiral, or helical motion in a fluid. A vortex often forms around areas of low pressure and attracts the fluid (and the objects moving within it) toward its center.

Velocity in the vortex is maximum next to the axis and inversely decreases with the radius.

Vortex enhances the desired solubility of pharmaceutical binder solute into the various solvents.

110. What should be characteristics of the solution preparation vessel?

• Zero dead leg and sanitary design components

• Stationary or mobile use

• Capable to handle wide temperature range (design as per requirement)

• The Internal surfaces of our preparation vessels are flush ground and mirror polished to <0.3 Microns Ra and electro-polished

• Easy to clean

• Adjustable speed of stirrer

• Adjustable temperature

• 21 CFR Part 11 compliant and EU Annex 11 Compliant

• Low maintenance and long service

111. What are the different particle size reduction mechanisms?

| Particle size reduction mechanisms | Description |

| Impact | Particle size reduction by applying an instantaneous force perpendicular to the particle/ agglomerate surface. The force can result from particle-to-particle or particle-to-mill surface collision. |

| Attrition | Particle size reduction by applying a force in a direction parallel to the particle surface. |

| Compression | Particle size reduction by applying a force slowly (as compared to Impact) to the particle surface in a direction toward the center of the particle. |

| Cutting | Particle size reduction by applying a shearing force to a material. |

112. What are the types of Equipment used for Particle Size Reduction/ Separation. Explain its Operating Principles.

| Types of Equipment | Operating Principles |

| Fluid Energy Milling | Particles are reduced in size as a result of high-speed particle-to-particle impact and/or attrition; also known as micronizing. |

| Impact Milling | Particles are reduced in size by high-speed mechanical impact or impact with other particles; also known as milling, pulverizing, or comminuting. |

| Cutting | Particles are reduced in size by mechanical shearing. |

| Compression Milling | Particles are reduced in size by compression stress and shear between two surfaces. |

| Screening | Particles are reduced in size by mechanically induced attrition through a screen. This process commonly is referred to as milling or deagglomeration. |

| Tumble Milling | Particles are reduced in size by attrition utilizing grinding media. |

| Separating | Particles are segregated based upon particle size alone and without any significant particle size reduction. This process commonly is referred to as screening or bolting. |

113. Explain Equipment Classifications for Particle Size Reduction/ Separation. Give examples of Equipment for each classification.

| Equipment type | Sub classification description | Sub classification |

| Fluid Energy Mills | Fluid energy mill subclasses have no moving parts and primarily are distinguished from one another by the configuration and/ or shape of their chambers, nozzles, and classifiers. | Tangential Jet Loop/ Oval Opposed Jet Opposed Jet with Dynamic Classifier Fluidized Bed Fixed Target Moving Target High Pressure Homogenizer E.g. Jet mill |

| Impact Mills | Impact mill subclasses primarily are distinguished from one another by the configuration of the grinding heads, chamber grinding liners (if any), and classifiers. | Hammer Air Swept Hammer Conventional Pin/ Disc Cage E.g. Hammer millPin mill Impact millCage millDisk millBall mill |

| Cutting Mills | Although cutting mills may differ from one another in whether the knives are movable or fixed and in the classifier configuration, no cutting mill subclasses have been identified. | No sub class E.g. MultimillComill |

| Compression Mills | Although compression mills may differ from one another in whether one or both surfaces are moving, no compression mill subclasses have been identified. | No sub class E.g. Roller mill |

| Screening Mills | Screening mill subclasses primarily are distinguished from one another by the rotating element. | Rotating Impeller Rotating Screen Oscillating Bar E.g. MultimillComill |

| Tumbling Mills | Tumbling mill subclasses primarily are distinguished from one another by the grinding media used and by whether the mill is vibrated. | Ball Media Rod Media Vibrating E.g. Ball millTubular Rod Mills |

| Separators | Separator subclasses primarily are distinguished from one another by the mechanical means used to induce particle movement. | Vibratory/ Shaker Centrifugal E.g. Vibro sifterUltra Centrifugal Mill |

Source: fda.gov

114. What is Blending and Mixing?

Blending and Mixing is the process of reorientation of particles relative to one another in order to achieve uniformity.

115. What are the Operating Principles of different equipment for Blending and Mixing?

| Types of Equipment | Operating Principles |

| Diffusion Blending (Tumble blending) | Particles are reoriented in relation to one another when they are placed in random motion and interparticular friction is reduced as the result of bed expansion (usually within a rotating container). |

| Convection Mixing (also known as paddle or plow mixing) | Particles are reoriented in relation to one another as a result of mechanical movement. |

| Pneumatic Mixing | Particles are reoriented in relation to one another as a result of the expansion of a powder bed by gas. |

116. Equipment Classifications used for Blending and Mixing

| Equipment type | Sub classification description | Sub classification |

| Diffusion Mixers (Tumble) | Diffusion mixer subclasses primarily are distinguished by geometric shape and the positioning of the axis of rotation. | • V-blenders• Double Cone Blenders• Slant Cone Blenders• Cube Blenders• Bin Blenders• Horizontal/ Vertical/ Drum Blenders• Static Continuous Blenders• Dynamic Continuous Blenders |

| Convection Mixers | Convection blender subclasses primarily are distinguished by vessel shape and impeller geometry. | • Ribbon Blenders• Orbiting Screw Blenders• Planetary Blenders• Forberg Blenders• Horizontal Double Arm Blenders• Horizontal High Intensity Mixers• Vertical High Intensity Mixers• Diffusion Mixers (Tumble) with Intensifier/Agitator |

| Pneumatic Mixers | Although pneumatic mixers may differ from one another in vessel geometry, air nozzle type, and air nozzle configuration, no pneumatic mixer subclasses have been identified. | No sub lass |

Source: fda.gov

117. What is Granulation

Granulation is the process of creating granules. The powder morphology is modified through the use of either a liquid that causes particles to bind through capillary forces or dry compaction forces.

The process will result in one or more of the following powder properties:

Enhanced flow;

Increased compressibility;

Densification;

Alteration of physical appearance to more spherical, uniform, or larger particles;

And/or enhanced hydrophilic surface properties.

118. What are the Operating Principles of different Granulation?

| Types of Granulation | Operating Principles |

| Dry Granulation | Dry powder densification and/or agglomeration by direct physical compaction. |

| Wet High-Shear Granulation | Powder densification and/or agglomeration by the incorporation of a granulation fluid into the powder with high-power-per-unit mass, through rotating high-shear forces. |

| Wet Low-Shear Granulation | Powder densification and/or agglomeration by the incorporation of a granulation fluid into the powder with low-power-per-unit mass, through rotating low-shear forces. |

| Low-Shear Tumble Granulation | Powder densification and/or agglomeration by the incorporation of a granulation fluid into the powder with low-power-per-unit mass, through rotation of the container vessel and/or intensifier bar. |

| Extrusion Granulation | Plasticization of solids or wetted mass of solids and granulation fluid with linear shear through a sized orifice using a pressure gradient. |

| Rotary Granulation | Spheronization, agglomeration, and/or densification of a wetted or non-wetted powder or extruded material. This is accomplished by centrifugal or rotational forces from a central rotating disk, rotating walls, or both. The process may include the incorporation and/or drying of a granulation fluid. |

| Fluid Bed Granulation | Powder densification and/or agglomeration with little or no shear by direct granulation fluid atomization and impingement on solids, while suspended by a controlled gas stream, with simultaneous drying. |

| Spray Dry Granulation | A pumpable granulating liquid containing solids (in solution or suspension) is atomized in a drying chamber and rapidly dried by a controlled gas stream, producing a dry powder. |

| Hot-melt Granulation | An agglomeration process that utilizes a molten liquid as a binder(s) or granulation matrix in which the active pharmaceutical ingredient (API) is mixed and then cooled down followed by milling into powder. This is usually accomplished in a temperature controlled jacketed high shear granulating tank or using a heated nozzle that sprays the molten binders(s) onto the fluidizing bed of the API and other inactive ingredients. |