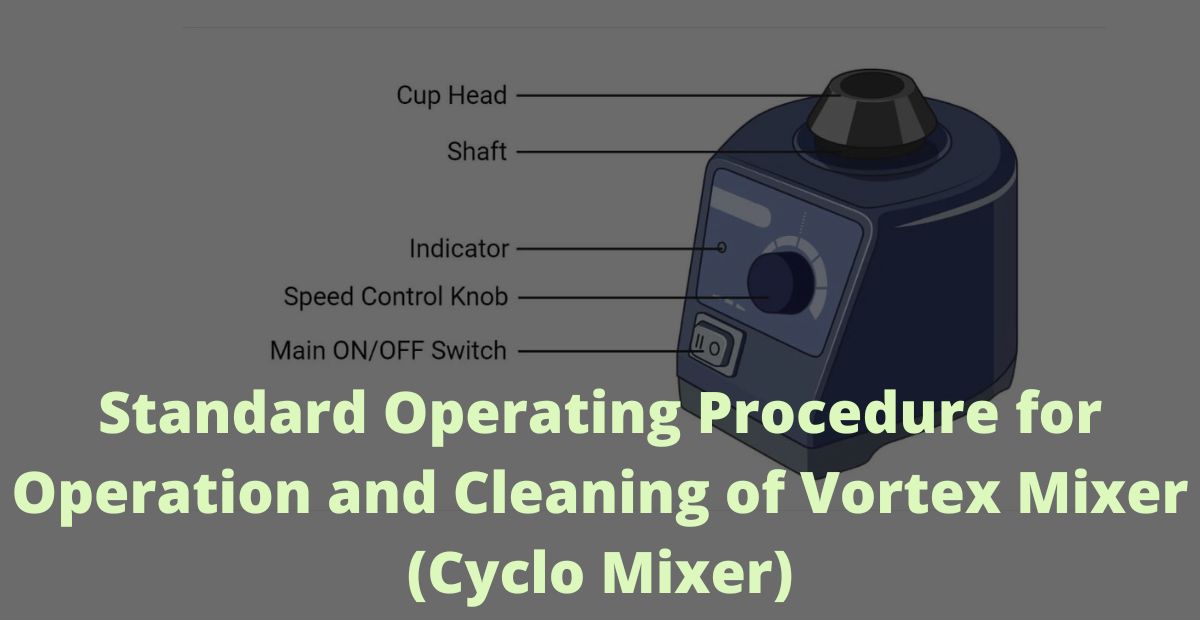

Standard Operating Procedure for Operation and Cleaning of Vortex Mixer (Cyclo Mixer)

1.0 Purpose:

To lay down a procedure for Operation and Cleaning Vortex Mixer (Cyclo Mixer)

2.0 Scope:

The scope of this procedure is applicable for Operation and Cleaning Cyclo Mixer (Vortex Mixer), Make – Remi.

3.0 Responsibility:

QC Personnel: To operate and clean cyclo mixer (Vortex Mixer).

Head QC/Designee: To monitor the activity.

4.0 Definitions:

NA

5.0 Procedure:

5.1 Ensure that the speed and heat control knobs are to the ‘0’ position and the corresponding switches are in “OFF” position before the magnetic stirrer is connected to the power supply.

5.2 Place the magnetic stirrer on the rigid level table or bench, which is free from vibration. Connect the magnetic stirrer to 230 Volts A.C. mains having proper earthing.

5.3 Start the speed regulator knob gradually during operation.

5.4 Operation:

5.4.1 Connect the CM-101 three pin power plug to a suitable three Pin 230 V AC power socket having proper earthing. When the unit is connected to power supply the diamond lamp will Glow. Now you have two options.

5.4.2 Direct ON: By this the vibrator will start directly and speed can be controlled by the regulator.

5.4.3 Load: By this means the unit will start only when the rubber top is loaded by tube with gentle press the rubber tube.

5.5 Cleaning:

5.5.1 Disconnect the power supply of the cyclo mixer.

5.5.2 Clean the outer surface of instrument with wet clean cloth followed by dry clean cloth.

6.0 Acceptance Criteria:

Not applicable.

7.0 Frequency:

Operation: As and when required.

Cleaning: As and when required.

8.0 Format for recording:

Not applicable