Most common 18 tablet defects at compression stage

Download Free High-Resolution Poster of Tablet Defects – refer to the end section of this article.

Tablet defects occur because of various reasons, which can be easily prevented from occurrence. To eliminate the possibility of defects in the tablets, the process of tablet manufacturing should be fully understood by the manufacturer.

Adequate scientific and academic knowledge along with hands-on training of tablet manufacturing, setting of the machine, and continuous monitoring plays a vital role in manufacturing high-quality tablets.

The technician should have adequate knowledge about the setting of the machine, trouble shooting, and the skill to operate the machine to manufacture high-quality products.

What are the common tablet defects at compression stage?

There are following commonly observed Tablet-Defects:

(01) Weight variation

(02) High friability

(03) High or low hardness (resistance to crushing)

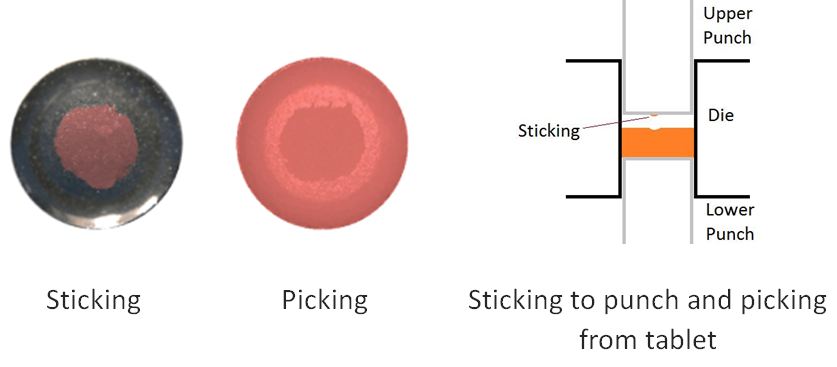

(04) Sticking

(05) Picking

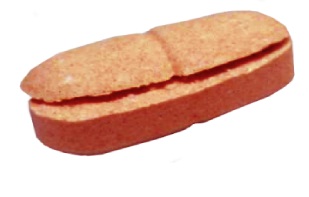

(06) Capping

(07) Laminating

(08) Chipping

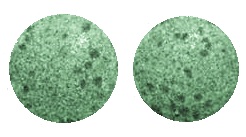

(09) Mottling

(10) Double press or impression

(11) Cracking

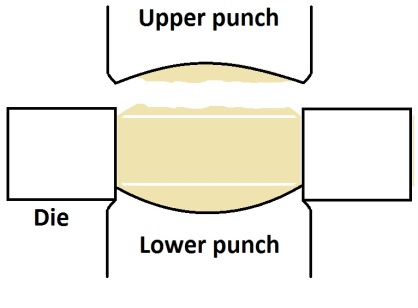

(12) Binding

(13) Edging or Flashing of tablet

(14) Disintegration time abnormality

(15) Black Spot/ particles/ fiber

(16) Improper embossing or debossing

(17) Layer separation

(18) Improper Layers

To get FREE High Resolution Tablet Defects Poster, refer end section of the page.

Weight variation

This tablet defect occurs when weight of individual tablet is beyond the specification criteria.

High friability

The condition of tablets being friable. The tendency of tablets to break into smaller pieces or weight loss of powder from the tablets due to mechanical action such as transportation condition. Loss occurs on outer surface. When percentage loss is more than 1%, it is considered as high friability.

High or low hardness (resistance to crushing)

When tablet hardness found out of specification criteria (upper limit or lower limit). Hardness limits are determined during development phase of product.

Sticking

Sticking is a defect wherein the portion of tablet surface adhere to the punch or the wall of die during tablet compression activity.

Picking

Picking is a counter part of the sticking. When part of the tablet surface adhes to a punch or a die wall, the produced tablet is with eroded surface. Tablet surface will not remain even.

Capping

Capping (or splitting) occurs when tablet upper layer or tablet lower layer partially get separated or completely gets separated from the main table body. This phenomenon occurs during ejection of tablet from the table press.

Lamination

Lamination of tablets means slitting of a tablet layers, parallel into 2 or >.

Chipping

When edges of tablets erode during manufacturing or handling called as Chipping of tablets.

Mottling

Mottling of tablet is refers to unequal or ununiformed distribution of color on tablet.

Double press or impression

Double impression means embossing or break or score line appears two time.

Cracking

Cracking of tablets means slight cracks appear on tablet surface.

Binding

The term binding is used when tablets sticks to the die. When such scenario occurs, ejection of table from the die does not happen properly.

Tablet Edging or Flashing

Tablet Edging or Flashing means observation of burrs or sharp edges on the edges of tablet.

Disintegration time abnormality

Too fast or too slow disintegration of tablets.

Black Spot/ particles/ fiber

Observation of black spot or particles or fiber which could be indigenous or foreign matter or contaminant.

Improper embossing or debossing

The defect because of improper embossing or debossing of letter, logo or monogram.

Layer separation

When layers of tablet gets separated, it is called Layer separation. This is usually seen in tablets such as bilayer tablet.

Improper Layers

Mainly appears in layered tablets such as bilayer tablet. In this type of defect, layer does not distinguished sharply.