July 10, 2021: Pharmaceutical Interview Questions and Answers

1. Explain the construction of tablet friability tester, testing process and limit.

i. Plastic chamber that revolves at 25 rpm

ii. For testing it operates for 100 revolutions

iii. Dropping the tablets from a Distance of 6 inches in the tester

iv. The tablets are weight before and after rotation. De-dust tablets after rotation. Perform calculation in percentage weight loss.

v. Limit of friability testing is NMT 1.0 %

2. What is Disintegration Time (DT) Test?

Disintegration time is time taken to breakdown of the tablets into granules or primary powder particles.

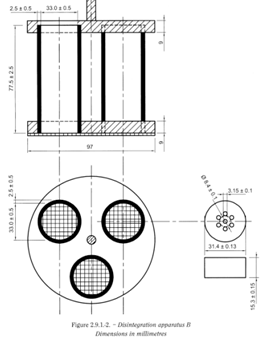

3. Explain the of tablet disintegration tester parts.

i. Basket rack assembly

ii. A suitable vessel for the immersion liquid

iii. Heater for fluid heating between 35°C and 39°C

iv. Basket in the immersion in fluid at frequency rate between 28 and 32 cpm (Cycle per minute)

v. Distance of up and down not less than 5 cm and not more than 6 cm

4. What are the common tablet defects at compression stage?

Weight variation

High friability

High or low hardness (resistance to crushing)

Sticking

Picking

Capping

Laminating

Chipping

Mottling

Double press or impression

Cracking

Binding

Edging or Flashing of tablet

Disintegration time abnormality

Black Spot/ particles/ fiber

Improper embossing or debossing

Layer separation

Improper Layers

5. What are the different types of tablet coating defects?

Blistering

Chipping

Cratering

Sticking or Picking

Pitting

Blooming

Blushing

Color Variation

Infilling

Orange Peel or Roughness

Cracking or Splitting

Twinning Erosion

Bridging